Product Basics

Yes, we offer full technical support including installation guidance, process training, troubleshooting, and long-term maintenance services.

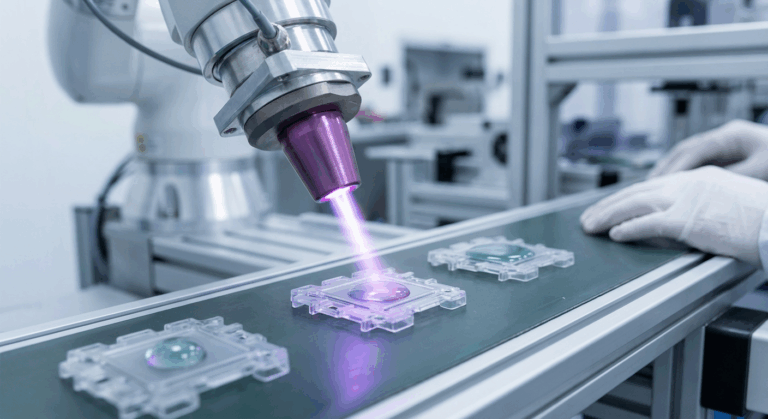

Plasma surface treatment uses ionized gas to clean, activate, or modify material surfaces, improving adhesion, wettability, and coating performance.

Our systems treat plastics, rubber, metals, ceramics, glass, composites, semiconductors, and various advanced materials.

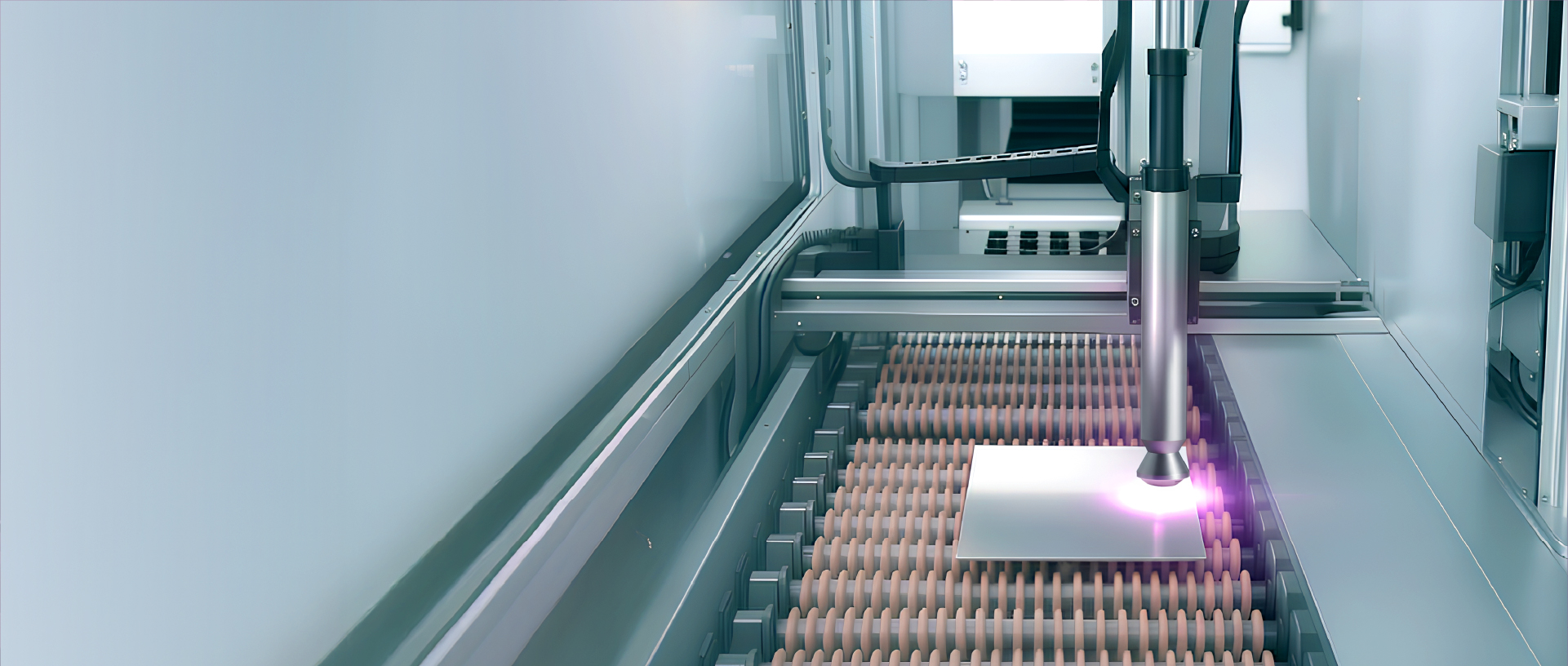

Atmospheric plasma is used inline without a chamber for fast activation, while vacuum plasma provides deeper cleaning, finer control, and higher precision.

Common gases include oxygen, argon, hydrogen, nitrogen, and air, each providing different cleaning or activation effects.

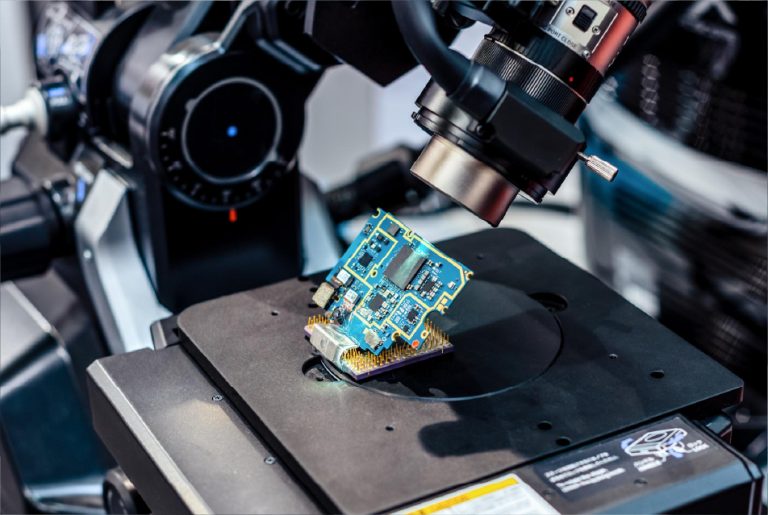

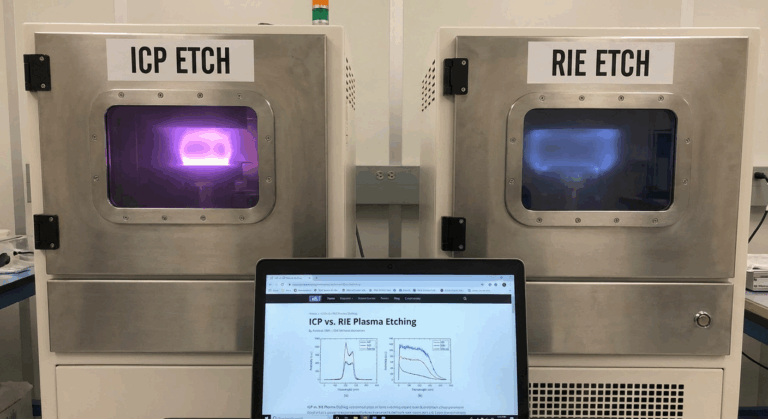

Yes, our ICP and RIE systems are designed for precise etching, ashing, and photoresist stripping in semiconductor and microfabrication processes.

Selection depends on your material, surface requirements, throughput, and process type—our team provides customized recommendations for each project.